This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Home > AQL Calculator

AQL Calculator

It’s important for there to be a certain level of product quality and an efficient method for recognizing those standards. Quality control is important as it can minimize risks, save money, and time in production. Suppliers can also be managed more easily, as a company you have better bargaining power and brand protection if have a plan in place.

Acceptable Quality Limit (AQL) sampling is a practical and effective way to perform quality assurance on an order of manufactured goods to reduce any risks prior to officially accepting it. There are three AQL levels that a product can be classified by. Each one describes a defect level: critical defects, major defects, or minor defects. We can classify a product to determine which one they fall into by using an AQL calculator instead of tables to produce sample sizes and defect numbers quicker.

HQTS Quality Inspections AQL Calculator

AQL Sampling Explained - HQTS Video

How is AQL calculated?

There are two tables that are used to determine the AQL of products. They are both used to determine the sample size for inspection and the acceptable defective units. The AQL Sampling Chart offers more options including inspection levels and standards for unique cases.

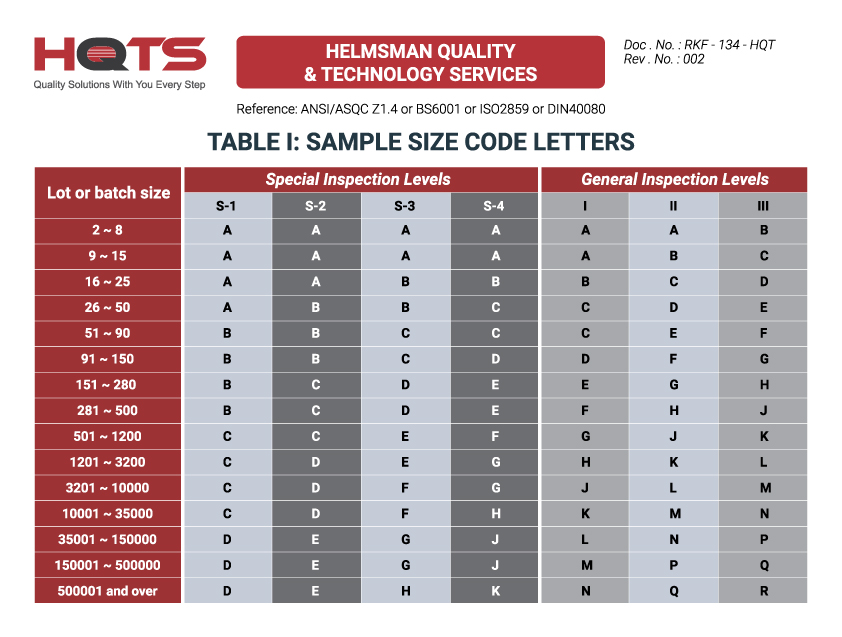

Table 1: Sample Size Code Letters

The most common standard is AQL Table 1 (below) which is used as a fundamental tool when carrying out quality control inspections. The AQL Table makes it easy for the buyer and manufacturer and quality control provider to come together in agreement on quality inspection standards. Table 1 also helps to provide the sample size code letters.

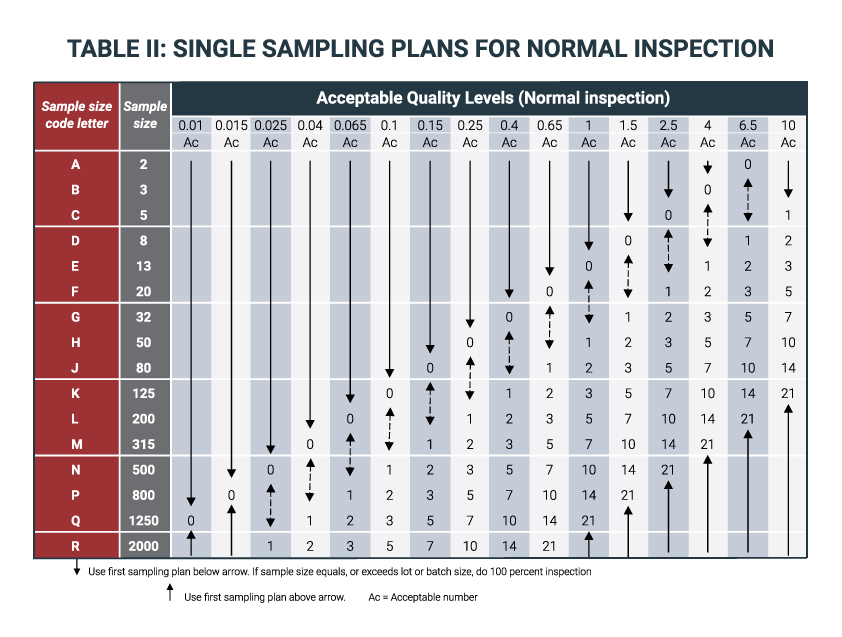

Table 2: Single Sampling Plans for Normal Inspections

Table 2 includes single sampling plans for normal inspections and the check marks on the table show how many products have passed whereas, the cross shows how many have failed. The up arrows show that you should use the sampling size above the arrow and if you see an arrow that equals or exceeds the batch size, you should go ahead and complete a 100% inspection or a piece-by-piece inspection. Looking at the down arrows, you should use the first sampling plan below the first down arrow.

What is an AQL Inspection?

AQL is a fundamental measure of standards used to complete product inspections. In line with ISO 2859-1, it refers to the lower limits of acceptable standards for consumer products over the course of a number of inspections. AQLs should be used to determine whether or not a product has met a client’s specifications.

AQLs can be set for a percentage or number of critical, major and minor defects. Critical defects – 0% are not acceptable as a user could be harmed, the product is not compliant with regulations, or the defect results in product failure.

Major defects – 2.5% represents defects that result in the product being considered unacceptable by the end user and minor defects – 4%, are a failure to meet specifications in ways that most buyers would still accept.

What are the benefits of AQL quality control inspections?

AQL could be a preferable method to testing every single product in a batch. If you are only purchasing products in small volumes, you probably have the resources to test everything but as quantities rise, rigorous testing becomes harder to manage in terms of time and cost.

AQL is a robust statistical model that has been used very successfully over many years. However, an AQL inspection will not guarantee a defect-free experience as some defects will go undetected. AQL will simply allow you to select the percentage of defects that you are willing to accept and can be a sensible option when it comes to gaining valuable insights about your products in your supply chain.

About HQTS

AQL sampling is a practical and effective way to perform quality assurance on an order of manufactured goods to reduce the risk prior to accepting an order. Backed by the industry knowledge and experience of nearly 1,500 professionals, in more than 20 countries, HQTS is well-suited to be your partner in quality.

Combine this with HQTS’ quality standards and services and you have a powerful, profitable and productive commercial proposition. HQTS will help ensure your packaging is up to the task and that your goods are effectively secure and protected throughout the transport process. Contact us here today for more information or any questions you may have.