In modern manufacturing, laser cutting machinery is increasingly popular due to its precision, efficiency, and versatility in cutting various materials. Given its complexity, with advanced technologies and high-powered lasers, even small deviations can have a big negative impact.

To protect their investments, businesses often hire third-party inspectors to assess laser cutting machinery at manufacturing sites in China or other overseas locations. In this article, we’ll dive deep into the key elements that are checked during these inspections.

What Should I Know Before Buying a Laser Cutter?

Many businesses are looking abroad for laser cutting machinery, with China being a prominent choice. However, exercising caution is important. Particularly when dealing with new suppliers for high-value products like laser cutting machinery. For more information related to how we assists buyers in verifying their supplier’s legitimacy, refer to our supplier audit guide.

What Are Problems With Laser Cutting Machines?

Below, we’ve listed some of the main problems that buyers experience when purchasing laser cutting machinery.

- Compatibility with Other Materials: Evaluate the machine’s capability to handle different types of materials without compromising quality, precision, or causing damage. For example, review the manufacturer’s specifications, conduct material compatibility testing, or consult with the manufacturer or supplier.

- Precision and Calibration Issues: Check that the equipment is calibrated correctly, as any deviation can negatively impact cutting precision.

- Optical Component Damage: Verify that all intricate components, such as mirrors and lenses, are functional on-site, before shipment.

- Overheated Cooling System: Inefficient or damaged cooling systems can lead to fluctuations in laser performance, affecting the overall efficiency and reliability of the machine.

These are just a few factors that you need to consider when purchasing quality laser cutting machinery. One way to mitigate risks is to perform a third inspection on-site before shipment. Below, we’ll dive deeper into how these inspections are performed.

Third Party Inspections of Laser Cutting Machines

Ensuring the highest reliability and safety standards for laser cutting machines involves a crucial step in the quality control process—third-party inspection.

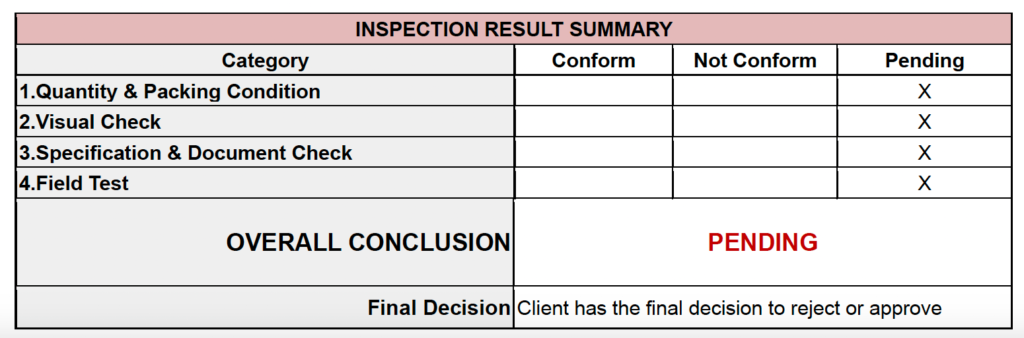

With years of expertise, HQTS has conducted many inspections of laser cutting machinery on behalf of our clients. These inspections can vary based on specific criteria and requirements. Below, we’ve outlined the main attention points, covering Quantity & Packing Condition, Visual Check, Specification & Document Check, and Field Tests.

1. Quantity Verification and Packaging Condition

The laser cutting machinery is complex equipment comprised of many intricate parts and accessories. One crucial aspect is for the inspector to conduct a quantity check to confirm whether the factory has all machinery and related parts ready, as specified in the purchase contract. Another key element is to verify that the manufacturer has used sufficient protective materials in the packaging to reduce the risks of damage during transportation.

In this situation, none of the products were packed yet. For example, only one stabiliser was found at the scene, and the factory mentioned that the rest would be ready before delivery. As a result, the inspector marked this criterion as “Pending.”

2. Visual Inspection

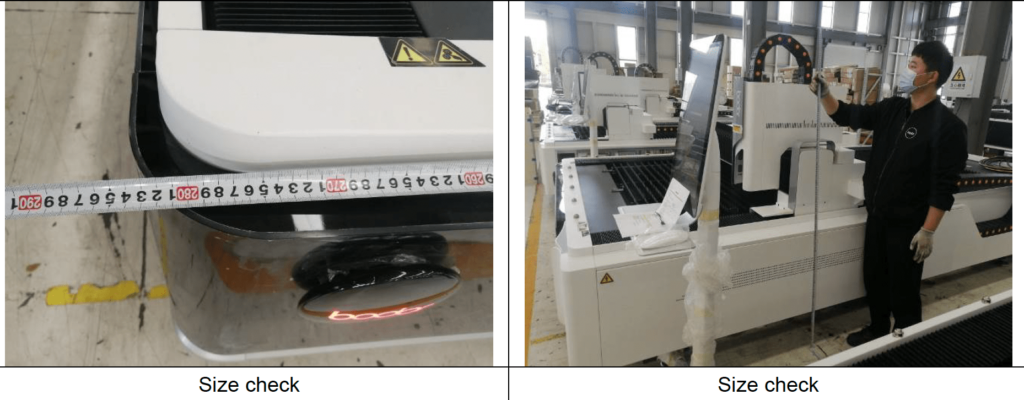

Another crucial aspect is to inspect the laser cutting machinery through a visual examination. The inspector will scrutinise the machine’s components, surfaces, and overall structure to identify any potential defects, irregularities, or deviations from the required standards.

This involves a thorough evaluation of various factors such as:

Appearances:

- Rust, scratches, abrasion marks, bumps, and other visible imperfections.

- Oxidation, deformation, sharp edges, and any other observable flaws.

- Color deviations, warpage, twists, and other factors that may impact structural integrity and performance.

- Checking for corrosion, debris, organic substances, oil contamination, dust, and other foreign elements that could compromise the machinery’s functionality.

Additionally, the visual inspection includes an examination of the paint condition. For example, checking for any signs of peeling, air bubbles, impurities, or other issues that might affect the aesthetics/protective properties of the coating.

Warning Signs and Emergency Stops:

- Movable components, mechanical hazards, electric hazards, thermal hazards, etc.

- Efficiency, sign labels, etc.

Name Plate:

- Date of production, identity number, supplier/manufacturer name, product model number, etc.

Through this detailed visual inspection, the goal is to ensure the laser cutting machinery meets the highest standards in terms of performance, safety, and overall quality.

3. Specification & Document Check

The third element is to inspect and verify that the machinery conforms to the specifications, and all detailed documentations are present. The goal is to confirm that the laser cutting machinery not only meets the specified technical requirements but is also accompanied by complete and accurate documentation for proper operation and maintenance. This includes:

- Checking that the instruction manual and maintenance manual are available in both the import country and exporter’s country language.

- Cross-checking the machine’s quality certificates.

- Verifying self-exam records, such as the ex-factory test report or the components test report.

4. Field Test and Functional Operation

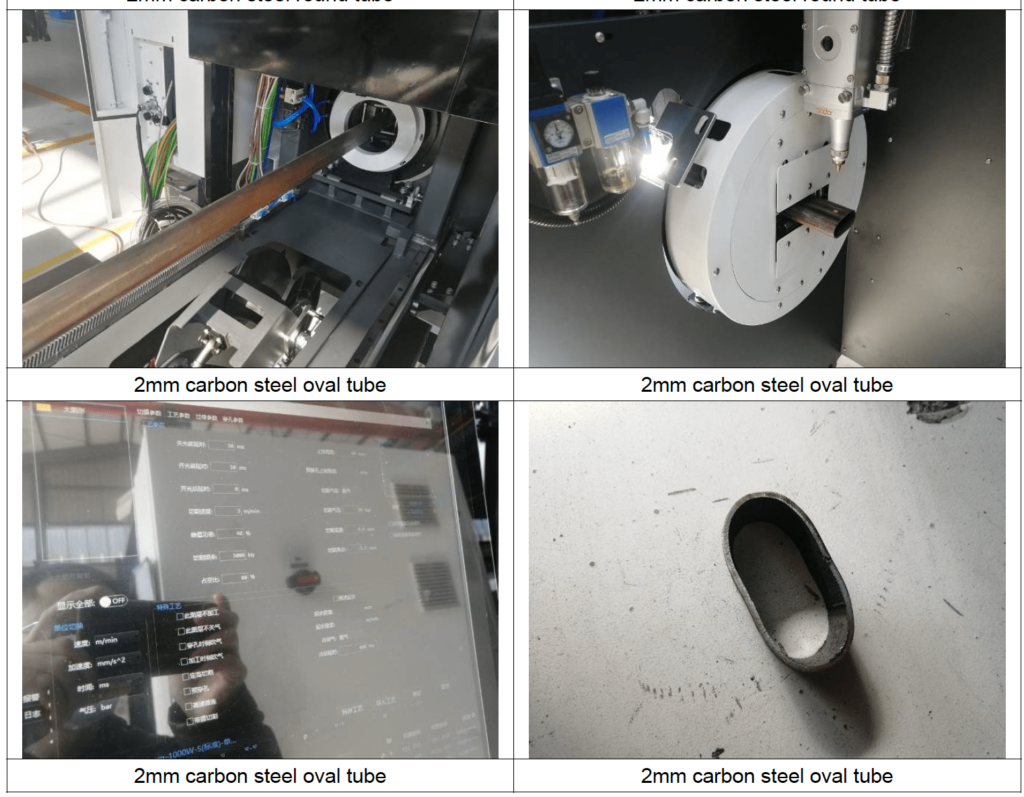

Last, but not least, comes the main component in the third-party inspection of laser cutting machinery. It’s imperative that the machinery is tested to its true capabilities during field tests and functional operations. These tests are generally divided into different parts, which include:

- Assembly Check: Verifying the construction of the machinery (e.g., any physical damage, stability, reliability), Checking major components (cooling system, energy supply, lubrication system, etc.), Inspecting the transmission system (belt, chain, gear, pulley), Examining electronic and electric parts (insulation, wiring, switch, etc.).

- Functional Operation:Assessing designed functions, protective functions, synchronisation, and consistency.

- Monitor and Indicator: Ensuring information readability and correctness of signal translation.

- Imitative Trial: Checking and evaluating the produced product according to specifications or general requirements.

This testing procedures aims to verify not only the structural integrity and construction of the laser cutting machinery but also its functional capabilities in alignment with the specified technical requirements.

Conclusion: A Guide to Third-Party Inspections of Laser Cutting Machines

Laser cutting machinery holds significance across various industries, driven by its versatility, precision, and efficiency. However, the slightest deviation can negatively impact the quality of the final product, underscoring the importance of rigorous quality control.

The five key elements that we check during our inspections include Quantity & Packing Condition, Visual Check, Specification & Document Check, and Field Tests. It’s crucial to note that the specific checkpoints may vary based on the machinery undergoing inspection and the client’s requirements.

HQTS has served as a neutral third-party inspection company, assisting global companies in verifying product quality at their factories in Asia for more than 25 years. If you have any inquiries regarding our quality control services for laser cutting machinery, please don’t hesitate to reach out today to learn more.