Product Inspections

HQTS quality control inspections verify product quality and quantity to predetermined specifications.

The decrease in product life cycles and time-to-market increases the challenge to deliver quality products in a timely manner. When your product fails to meet your quality specifications for market acceptance, the result can be loss of good will, product and revenues, delayed shipments, wasted materials, and the potential risk of a product recall.

Quality Control Inspections Procedure

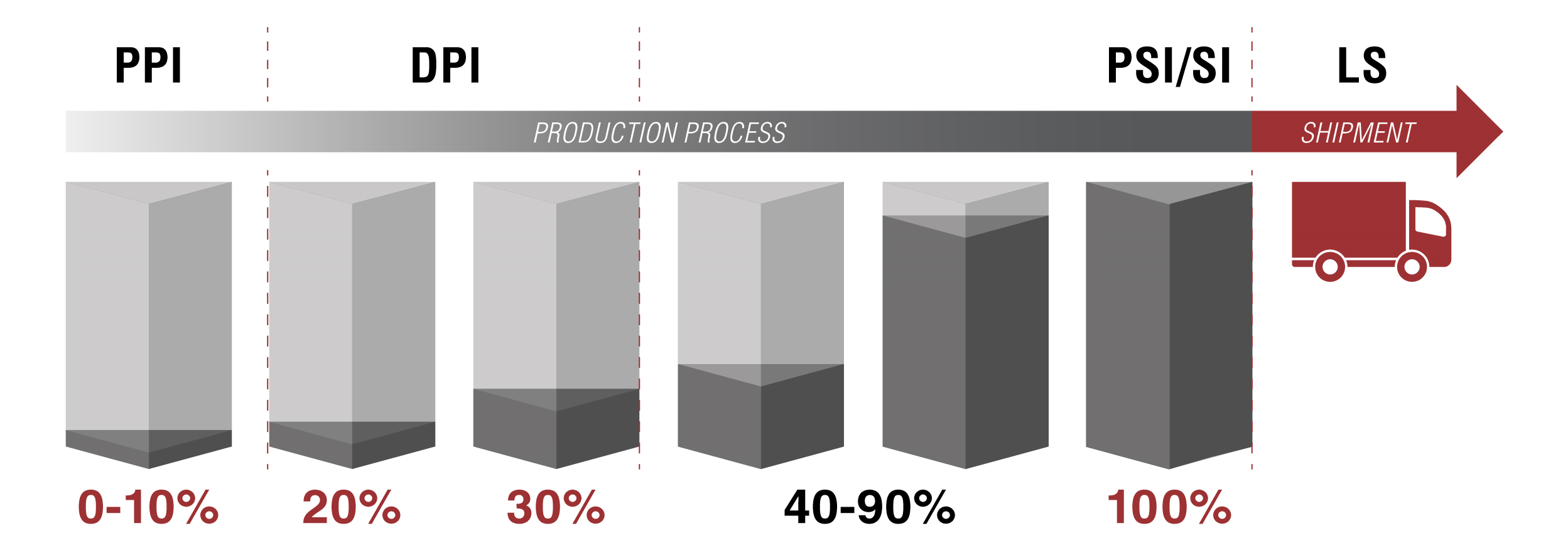

Typical quality control inspections include four primary steps. Depending on the product, your experience with the supplier, and other factors, any one, or all of these, may apply to your needs.

Pre-production Inspections (PPI)

Prior to production, our quality control inspection of raw materials and components will confirm whether these meet your specifications and are available in quantities sufficient to meet the production schedule. This is a useful service where you have had issues with materials and/or component replacements, or you are working with a new supplier and many outsourced components and materials are required during production.

During Production Inspections (DPI)

During production, the products are inspected to verify that quality requirements and specifications are being met. This process is useful in cases of repeated defects in production. It can help identify where in the process the problem occurs and provide objective input for solutions to resolve the production issues.

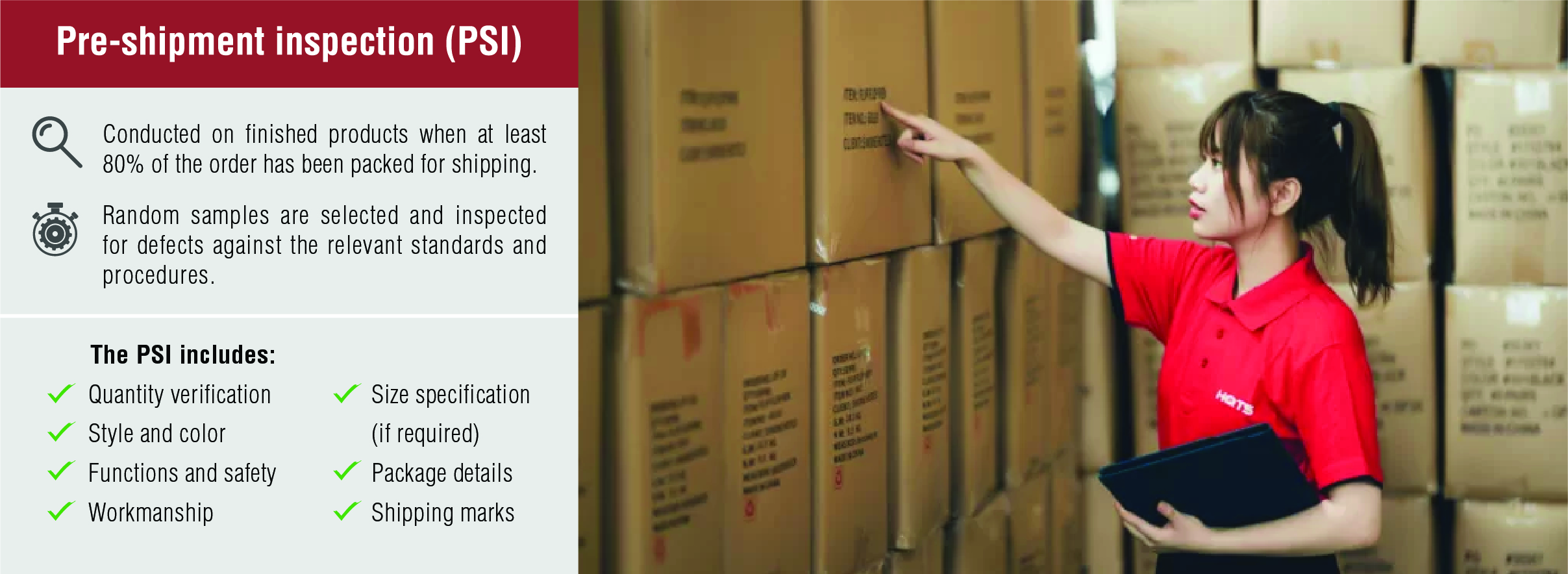

Pre-Shipment Inspections (PSI)

After production is completed, a pre shipment inspection can be done to verify that the goods being shipped have been manufactured according to your requirements. This is the most common service ordered, and works well with suppliers you have previous experience with.

Piece by Piece Inspections (or Sorting Inspection)

A Piece by Piece Inspection can be carried out as a pre or post packaging inspection. A piece by piece inspection is performed on every item to evaluate general appearance, workmanship, function, safety and etc. as specified by you.

Container Loading Inspections (LS)

Container Loading Inspection guarantees HQTS technical staff are monitoring the entire loading process. We check that your order is complete and securely loaded into the container before shipment. This is the final opportunity to confirm compliance with your requirements in terms of quantity, assortment, and packaging.

Benefits of Quality Control Inspections:

Quality control inspections at various stages of the production process can help you monitor product quality to ensure requirements are being met and to support on-time delivery.

With the right systems, processes and procedures of quality control inspections, you can monitor product quality to reduce risk, improve efficiency and ensure compliance with contractual or regulatory requirements, build a stronger and more resilient business with the potential to grow and surpass your competition; deliver consumer goods that really are as good as you say they are.

- Customers expect to buy qualified, health and safety products

- Ensure every procedure goes well at every production stage

- Verify quality at the source and don’t pay for defective goods

- Avoid recalls and reputation damage

- Anticipate production and shipment delays

- Minimize your quality control budget

Other QC Inspection Services:

Why are Quality Control Inspections important?

Quality expectations and the range of safety requirements that you must achieve become increasingly complex day by day. When your product fails to meet quality expectations within the marketplace, the result can be loss of good will, product and revenues, customers, delayed shipments, wasted materials and the potential risk of a product recalls.

HQTS has the right systems, processes and procedures to help you meet your requirements and deliver quality products in a timely manner.

Why HQTS?

Founded in 1987 and headquartered in China, as the leading third party inspection company in Asia, HQTS has excellent in-depth knowledge of quality control systems and processes, as well as holding all the necessary certificatation such as CNAS, CMA, GACC etc. With more than 1500 specialists, in more than 60 countries, we are able to hold an inspection service anywhere in Asia within 48 hours as well as anywhere in the world and offer an inspection and testing report within 24 hours.

No matter what industry you are in, apparel textile, toys and children products, footwear, hardgoods, food, electronics and electrical products, home appliance, automotive, construction and building, machinery and equipment, whether commercial or consumer facing, HQTS is dedicated to helping you meet the quality, safety and ethical standards you demand throughout your supply chain, thereby improving your competitiveness and efficiency in the global marketplace.