AQL stands for Acceptance Quality Limit and is a term related to the maximum number of defects that buyers and suppliers have agreed on in a batch. Importers can set different AQLs, including: critical, major and minor defects.

When exporting goods, most Asian export companies are familiar with this term and particularly use AQL 2.5 forms in purchase orders and AQL inspections. But what does AQL 2.5 mean, and how is it calculated? In this short guide, we’ll go through everything you need to know about AQL 2.5 and teach you how to read an aql chart.

What Is AQL?

When importing goods from a supplier, it is important to ensure that certain levels of product quality are maintained and to have an efficient method for assuring those levels of quality.

AQL sampling is a practical and effective way to perform quality assurance whilst ordering manufactured goods, helping to reduce any risks before officially accepting the items.

Listen to the video below if you want to learn how AQL is used in quality control inspection and how you can determine the AQL sample size within an AQL table.

What Are The Types of AQL?

Within the AQL sampling method, there are generally three main AQL levels used, and these include:

- Critical (0% defects)

- Major (2.5% defects)

- Minor (4.0% defects)

Critical defects (0%) are not acceptable at all, as the user could be harmed, major defects (2.5%) represent products being considered unacceptable by the end- user and minor defects (4%) fail to meet specifications in ways that most buyers would still accept.

Generally speaking, the level of accepted defective goods depends on the agreement between the supplier and the buyer, based on the level of risk they decide on. Products that pose more of a health risk will have a lower AQL threshold. Once an AQL Standard is agreed on, it will be used as a reference throughout the inspection process, determining the acceptable percentage for every defect in an order.

What Does 2.5 AQL Mean?

AQL 2.5 means the acceptable level of major defective goods is 2.5% of the total order quantity. If the batch produced contains a defect level that exceeds 2.5% defects, then the quality of the product is not living up to the agreement. The AQL 2.5 level is commonly used in the garment industry, Chinese manufacturers and more.

You can use the HQTS AQL Calculator for your quality inspection needs:

What Is an AQL Chart?

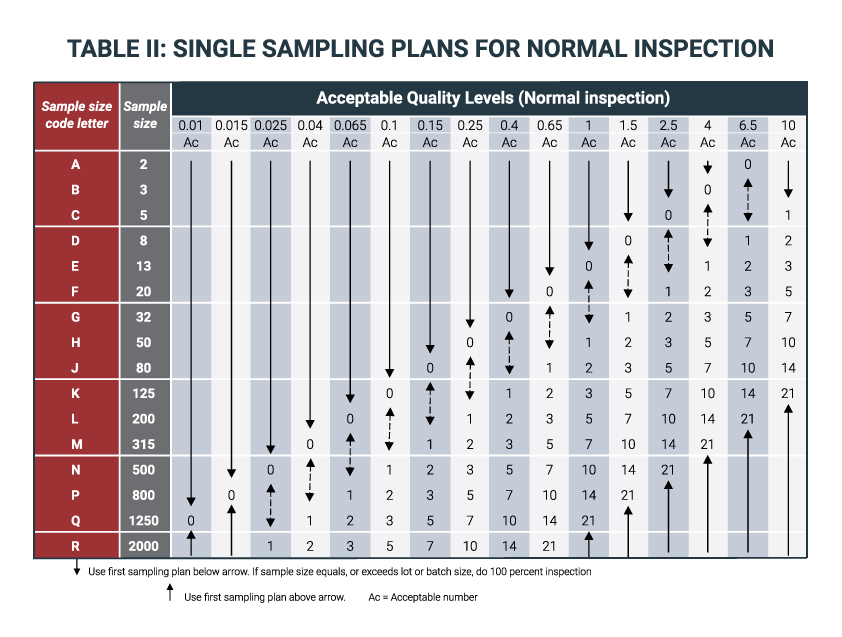

An AQL chart is a tool that can be used to determine the sample size for inspection purposes and the acceptable defective units. The AQL chart also offers more options, including inspection levels and standards for particular unique cases.

The most common standard is AQL Table 1. This is used as an important tool when carrying out quality control inspections, this AQL table simplifies the information for the buyer, the manufacturer and the quality control provider; as they can all come together and agree on set quality inspection standards.

How To Read an AQL Chart

Reading an AQL chart 2.5 is relatively straightforward.

The chart below displays a single sampling plan for when normal inspections are carried out, the check marks on the table show how many products have passed and the crosses show how many products failed. The up arrows determine the sampling size and if you see an arrow that equals or exceeds the batch size, you should complete a full inspection or a piece-by-piece inspection.

Why Is AQL Important in Quality Inspections?

AQL is a vital tool when performing sampling inspections, inspection teams can use an AQL standard to ensure the number of units inspected in a given sample is correct and the number of defective units that could cause a failure result is noted down. The AQL Standard determines the required sample size that needs to be inspected and the number of rejected units.

Inspecting a large number of units at once can be too difficult for manufacturers and therefore, incorporating a method such as AQL 2.5 can be extremely helpful for businesses.

Hence, AQL is a preferable method when you need to efficiently check whether the products in the batch are up to the defined quality standard. However, if you are only purchasing products in small volumes, your business may have the resources to test everything at once. But as quantities rise, piece by piece inspections can become harder to manage due to time restraints and costs.

AQL 2.5 is a robust, useful model that has successfully been used over many years. However, it is important to note AQL inspections do not guarantee a defect-free experience, as minor defects may go undetected. But, AQL allows you to select the percentage of defects that you are willing to accept/risk and it’s a secure option when it comes to gaining valuable insight into your supply chain, your products and your business.

After completing an AQL Inspection, the agency will issue a shipment certificate and this will clarify whether you passed or failed. The inspector will conduct a pre-shipment inspection before production commences and issue the pre-shipment report, this will be attached to your documents when shipping.

Conclusion: What Is an Acceptance Quality Limit (AQL 2.5)?

AQL 2.5 sampling is a practical and effective way to perform quality assurance on an order of manufactured goods to reduce the risk prior to accepting an order. Do you need help calculating how many units should be inspected during an inspection, or find out the acceptable defect number? Use our free AQL Calculator!

At HQTS, we use the AQL sampling method in our inspection services and always thoroughly document the results of the inspection in an inspection report. Backed by the industry knowledge and experience of nearly 1,500 professionals, in more than 20 countries, HQTS is well-suited to be your partner in quality. Contact us here today for more information or any questions you may have.