When you’re procuring Printed Circuit Boards (PCBs) from suppliers overseas, you could run into several problems and uncertainties. These can include issues like suppliers rushing to meet deadlines at the expense of quality, differences in production standards, and even dealing with dishonest suppliers.

To tackle these concerns, businesses frequently use impartial third-party PCB inspection service to examine the products at the manufacturing location before shipping. In this article, we’ll offer you an insider’s perspective on the key focus points during PCB first article inspection.

Navigating Third-Party PCB: PCB Inspections

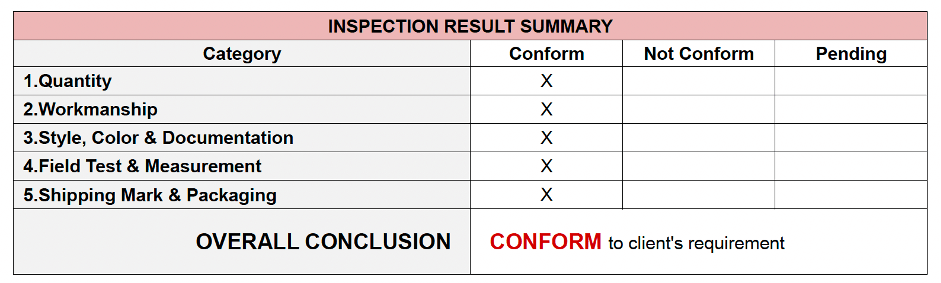

First of all, it’s important to note that the PCB first article inspection checklists can vary, contingent upon the applicable standards, criteria, and specific design requirements. Guided by the ISO 2859 sampling plan, we underscore the focus points in this article of a PCB quality inspection. These include: confirming quantities, evaluating workmanship, style and colour, reviewing documentation, conducting on-site tests and measurements, and examining shipping labels and packaging.

1. Quantity Verification

Printed Circuit Boards (PCBs) are complex elements, often connected with considerable production expenses. Receiving a quantity less than the initial order can initiate a sequence of events, potentially leading to interruptions in assembly lines and substantial financial setbacks.

Hence, verifying the exact quantity of PCBs before you receive your shipment is important. The inspector begins the inspection by cross-checking the total item count with the information provided in the purchase order.

2. Craftsmanship Evaluation

The overall quality of the PCB’s craftsmanship is important, as even minor imperfections can result in product malfunctions, reduced device longevity, and, in some cases, safety hazards.

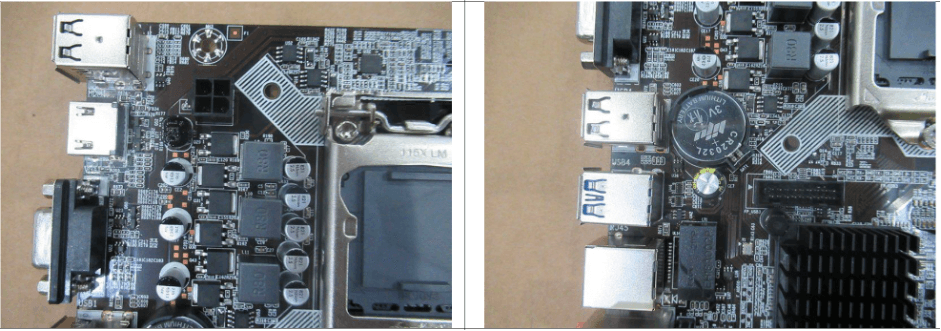

In this crucial phase, the inspector performs a detailed assessment of the PCB’s workmanship. This evaluation involves several critical assessments, such as:

- PCB Visual Inspection: Assessment of the PCB layout and its individual components to identify any visible defects using a PCB visual inspection. These defects can include missing or incorrectly positioned components.

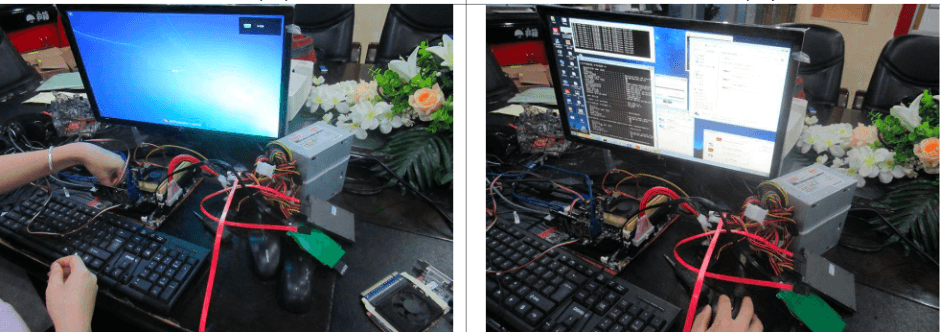

- PCB Functional Test: A series of PCB functional tests is carried out to verify that the PCB operates in alignment with its designated design and specifications. Some of these PCB testing methods provide results displayed on a computer interface, while others may trigger indicator lights or display information on a screen.

3. Aesthetics, Colour, and Documentation

Maintaining strict adherence to the established order is important. Even the slightest deviation from the designated design or specifications can result in operational challenges, especially within the intricate domain of electronic assemblies.

To uphold this consistency, inspectors are:

- Verifying Product Alignment: Verify that the delivered products match the purchase order and the specific product requirements.

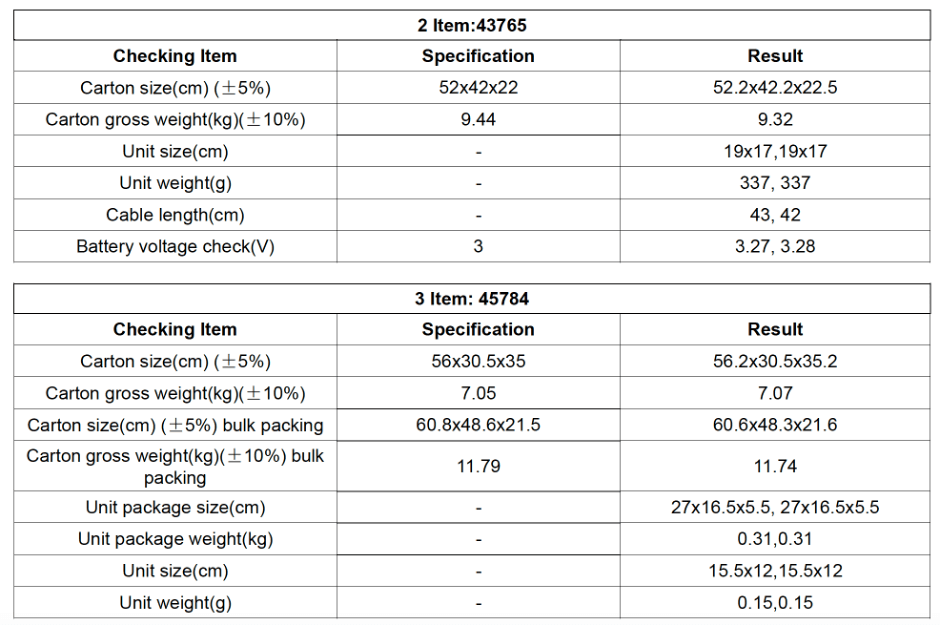

- Dimensional Precision: Verify that the PCB’s dimensions adhere to the specifications provided in the order through a dimension check.

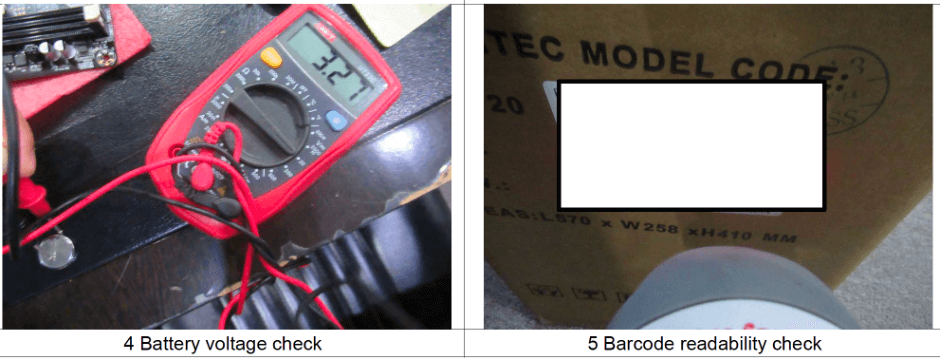

4. Field Testing and Precision Measurements

PCB field tests and precise measurements not only confirm the PCB’s physical characteristics but also evaluate its operational performance in various scenarios. Considering the critical role PCBs play in electronic devices, it is important to consistently maintain their operational excellence.

To guarantee the PCB’s optimal performance, a comprehensive array of tests and assessments is conducted:

- Voltage Validation: Monitor the voltage levels at crucial points on the PCB to confirm their alignment with the specified range and to evaluate their stability.

- Carton Weight: Verify that the carton’s weight matches the specified specifications and required standards.

- Odor Examination: Identify any unusual odours, which could be indicative of issues like burning or production anomalies.

- Barcode Precision: Assess the clarity and legibility of barcodes on the product, ensuring they conform to the necessary standards for identification and tracking.

- Product Weight Assessment: Measure the weight of the PCB and conducting a comparison with the specified benchmarks to verify that it aligns with the expected standards.

- Carton Quantity Verification: Verify the quantity of PCBs within each carton matches the order.

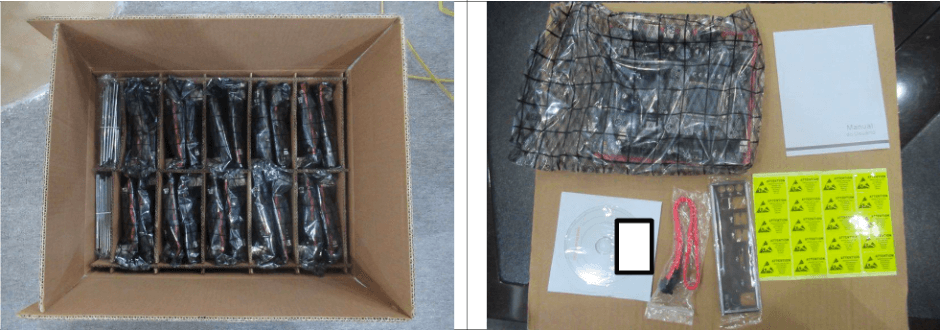

5. Shipping Marks and Packaging

Labeling is a critical aspect for accurate delivery of products and reducing the risk of losses or misdirection. Given the intricate nature of PCBs, protective packaging becomes indispensable in shielding them from potential damage during transportation.

In the last phase, the inspector examine the product’s shipping marks and labels. This process includes:

- Checking Shipping Marks: Review the shipping marks for clarity and correctness to ensure clear and accurate identification during transit.

- Cross-Referencing Shipping Details: Compare the supplied shipping information with the purchase documentation to verify alignment and accuracy.

- Validating Protective Packaging: Verify that the manufacturer has used sufficient protective materials in the packaging to reduce the risks of damage during transportation.

Conclusion

Ranging from quantity checks to assessing craftsmanship and confirming accurate shipping labels, the PCB inspection procedure involves several pivotal stages. These phases are not only crucial for preserving PCB integrity but also for ensuring the performance and longevity of the electronic devices into which they are integrated.

At HQTS, we take pride in our accreditation as a reputable third-party inspection company. We have 25+ years of experience and a network spanning 40+ countries. If you would like more information about PCB inspections or need to schedule your next inspection, please don’t hesitate to reach out to us today.