Quality control is a set of procedures an organisation undertakes to ensure that its products conform to a defined set of quality criteria or meet the relevant requirements of a client. There are many types of quality control activities, but they’re typically grouped into two broader categories: quality inspection and testing.

In this article, we’ll focus on the first category of quality control, namely quality inspections. We’ll provide you with an answer to the question “What is a quality inspection?” and cover the most common types of quality inspections used in quality control.

What is Quality Control?

Before diving into the topic of quality inspections, it’s important that we understand how they are related to quality control.

All in all, quality control is a process undertaken by a company to ensure that products meet certain standards. Or as defined by the ISO 9000: “A part of quality management focused on fulfilling quality requirements.”

In general, these are the quality benchmarks that are related to quality assurance and quality compliance.

- Quality assurance definition: Quality assurance is the process of verifying that products or services meet specific specifications and requirements.

- Quality compliance definition: Quality compliance is the process of making sure that a product meets the standards and rules specified by an organization or authoritative body.

Companies use a set of processes to assess whether or not a product is fit for its purpose and quality standards. These activities often include quality inspections (more on this later).

It’s important to note that quality control procedures may differ depending on the product or industry that they refer to. If you want to learn more about a particular product or industry, take a look at the following articles below:

- Quality Control in Garment Industry

- Furniture Quality Control

- Quality Control in Construction

- Pipe Welding Quality Control

- Glass Quality Control

- Food Quality Control

- Milk Quality Control

What Is Quality Inspection?

Quality Inspection is the process of evaluating and verifying if the inspected materials and products conform with the specified requirements.

There are multiple ways to achieve this, including having a quality inspector measure, examine, gauge, and test the product’s characteristics. Quality inspectors usually carry out a pre-established checklist which is based on the specifications of the product and/or client. They inspect the products to check whether they are fit for production or semi-finished goods, as well as finished goods ready for shipment to customers.

The results of the inspection are then compiled into a sample report, that indicates whether or not the product conforms to the specifications.

What Does a Quality Inspector Do?

Quality inspectors play a vital role in ensuring that products meet high standards and are produced in compliance with regulations.

They conduct inspections on manufacturing processes, product quality standards, company policies and manufacturing processes, and others. Their duties will vary depending on whether it is a company-employed quality inspector or a hired quality inspector from a third-party agency for a particular purpose (for example, quality inspections).

The duties of a quality inspector may include:

- Establish quality standards for all products and services provided by a company.

- Create rules for standards and communicate them to the relevant staff to ensure quality levels are maintained.

- Write documents to outline all standards clearly, creating references for employees.

- Work with all management-level employees to ensure they are maintaining any new standards and compliance with all relevant regulations.

- Perform random quality inspection checks on products or services to assess quality levels.

Quality inspectors help to review blueprints and specifications, as well as monitor operations to ensure they meet the relevant production standards. They can recommend adjustments to the manufacturing process, inspect and test materials used in final products, accept or reject finished items, remove products that fail to meet specifications, and report all inspection and test data.

Why Is the AQL Sampling Method used in Quality Inspections?

Inspectors often test samples when they conduct quality inspections.

The sampling method used in quality inspections often follows the ISO 2859-1 standard called AQL, or Acceptable Quality Limit. This is a sampling method technique that helps quality inspectors decide the maximum number of defective units that is acceptable when inspecting a production batch. The reason they use a sampling method is that it is the most cost-effective method of evaluating production batches.

They can also inspect individual units, but this requires more time and money (more on this later).

What Are the 4 Types of Quality Inspection?

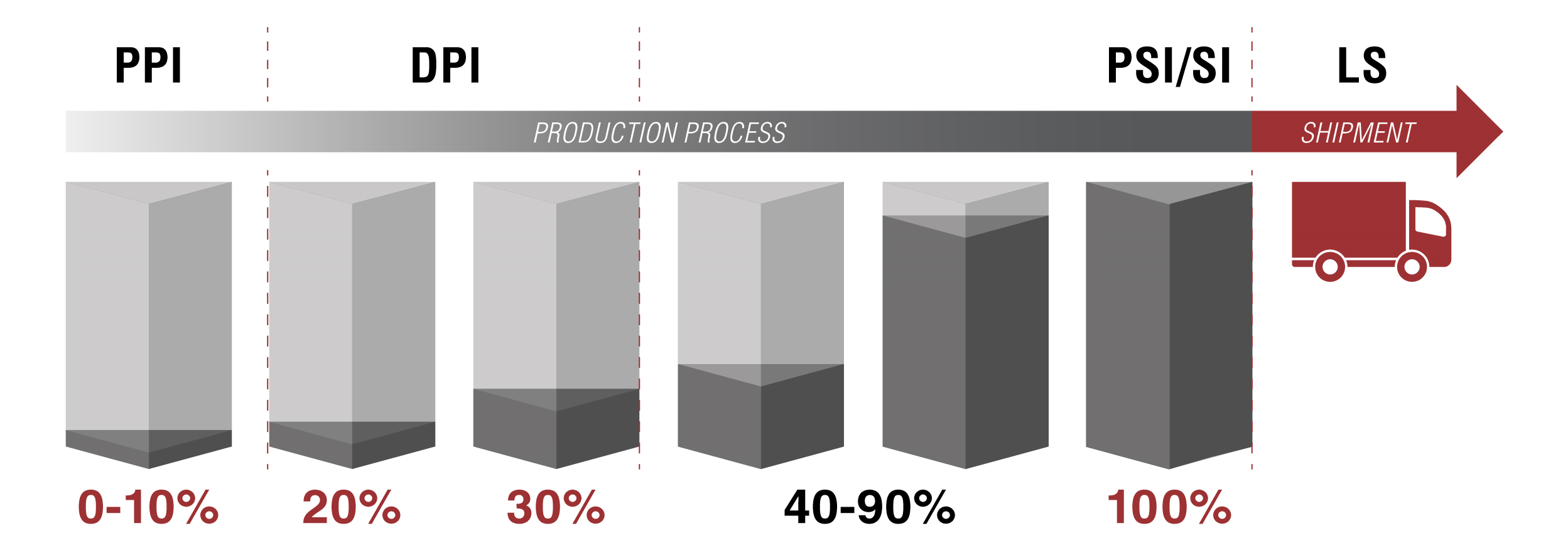

There are, in total, 4 types of inspection in quality control: Pre-Production Inspection, During Production Inspection, Pre-Shipment Inspection, and Container Loading/Unloading Inspections. As the name implies, each of the quality control methods is carried out at a different stage – and each of them has its own purpose in quality control and supply chain management. Depending on the product, experience with your supplier and other factors, one or all of these steps may apply to your business needs.

Pre-Production Inspection (PPI)

The Pre-Production Inspection (PPI) is conducted before the production process begins and helps to assess the quantity and quality of the raw materials and components and whether they conform to the relevant product specifications.

A PPI is beneficial when you work with a new supplier, especially if your project is a large contract that has critical delivery dates. This inspection can help to reduce or eliminate communication between you and your supplier on issues regarding production timelines, shipping dates, and quality expectations.

During Production Inspection (DPI)

During production inspection (DPI), also known as DUPRO, is a quality control inspection conducted while production is underway.

This step is particularly useful for products that are in continuous production and have strict requirements and/or when quality issues have been found prior to manufacturing during an earlier PPI. DPI inspections take place when only 10-15% of units are completed so that any deviations can be identified, feedback given, and any defects can be re-checked to confirm they have been corrected. It enables you to confirm that quality, as well as compliance with specifications, is being maintained throughout the production process.

It also provides early detection of any issues requiring correction, thereby reducing delays and rework.

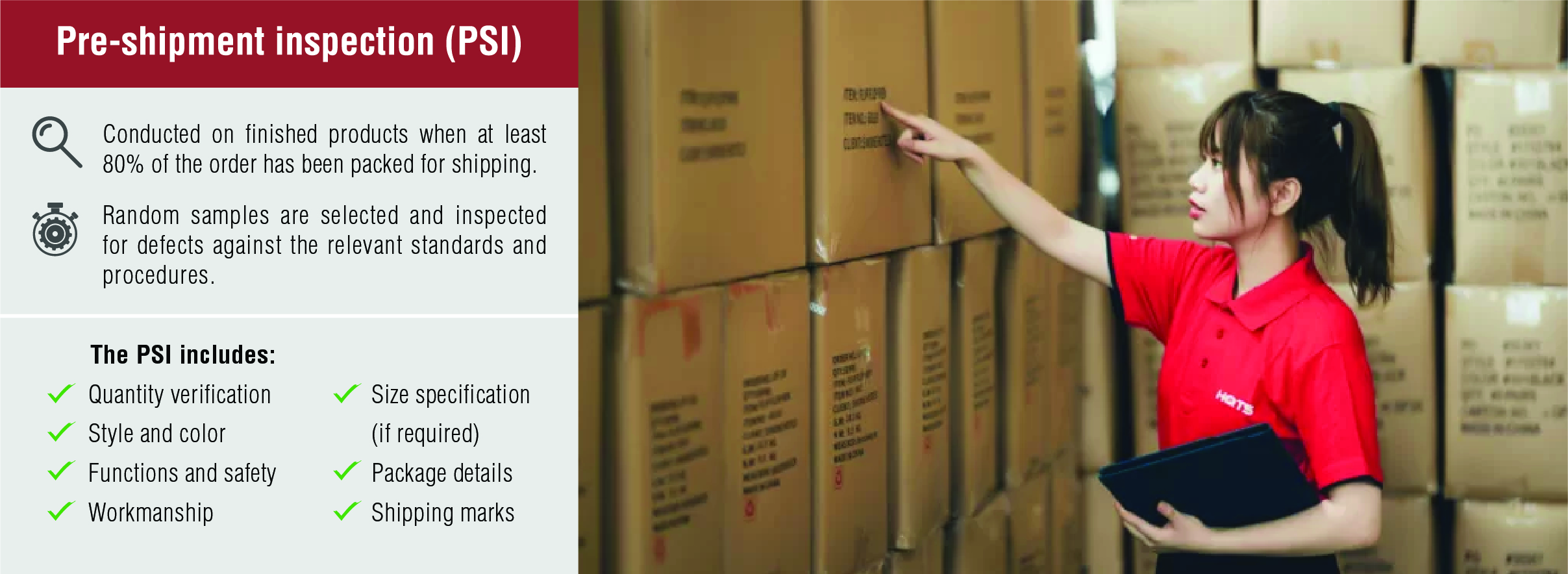

Pre-Shipment Inspection (PSI)

Pre-shipment inspections (PSI) are an important step in the quality control process and involve checking the quality of goods before they are shipped.

PSI ensures that production complies with the specifications of the buyer. This inspection process is conducted on finished products when at least 80% of the order has been packed for shipping. Random samples are selected and inspected for defects against the relevant standards and procedures.

Container Loading/Loading Supervision (LS)

Container loading and unloading inspections ensure your products are loaded and unloaded correctly.

Inspectors will supervise the whole process and ensure your products are handled professionally to guarantee their safe arrival at their final destination. This inspection will usually take place at your chosen factory while the cargo is being loaded into the shipping container and at the destination once the products have arrived and are being unloaded.

This process includes evaluating the condition of the shipping container and verifying all the product information, quantities, and packaging compliance.

Piece-by-Piece Inspections

In addition to the four types of quality control inspections above, another procedure also exists.

A piece-by-piece inspection involves checking each and every item to evaluate a range of variables including general appearance, workmanship, function, and safety. This inspection process can be carried out either before or after the packaging inspection. In the circumstance where the goods require particular attention to ensure compliance to specification or when the goods are high-value, a 100% inspection service should be performed.

Once the products have passed the inspection process, they will be sealed and certified with a sticker to ensure that every piece included in the shipment meets the specified quality requirements.

This inspection is particularly useful for goods that must be fully compliant and meet strict customer and market quality requirements. It can be carried out at any stage of the manufacturing process.

Conclusion: Basics in Quality Control: What Are the 4 Types of Quality Inspection?

Quality control is a set of procedures an organisation undertakes to ensure that its product conforms to the required standard of quality. These procedures are often undertaken by using quality inspections.

In quality control, there are 4 types of quality inspections, namely: Pre-Production Inspection, During Production Inspection, Pre-Shipment Inspection, and Container Loading/Unloading Inspections. Each of these types of inspection has its own purpose. It depends on where in the supply chain you want to deploy it, your product and your relationship with the manufacturer/supplier.

But conducting a quality inspection in China, or other countries thousands of miles away from your office can be challenging.

HQTS is a third-party inspection company with over 25 years of experience in quality assurance. We can help you conduct any of the above-mentioned types of inspections in quality control virtually anywhere in the world. Contact us today to find out how we can help you.